hardness test per astm-e8|astm e 84 fire rating : exporter In hardness testing according to Rockwell, the total test force is applied in two . Resultado da 13 de fev. de 2024 · Top 3 Casinos to play for REAL Money. 1. 100% up to £200 + 100 FS. 2. Up to £200 + 100 FS. 3. 100% Up to £20 + 100 FS. Сasino Fairground Slots is .

{plog:ftitle_list}

WEB31 de ago. de 2018 · Yes, you are right, this is a REAL MOBA, in Minecraft, what more abnormal than that ? Created by Gunivers, Hierarchy is a PvP map which needs at least 2 players. You can choose between 24 .

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area.In hardness testing according to Rockwell, the total test force is applied in two .

Bauer Fiber Classifier Φ100 distributor

As per ASTM E8, considerations for test speed are outlined for tensile testing of metallic materials, categorizing them as specimen strain rate, specimen stress rate, crosshead .1.1 These test methods cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point elongation, .Fokus khusus adalah pada test speed.ASTM E8 dan ASTM E8M mendukung lima cara berbeda untuk menentukan kecepatan pengujian. Mereka ditunjuk sebagai (a) Laju regangan spesimen, (b) Tingkat tegangan spesimen, (c) .

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

Laboratory Pulp Disintegrator distributor

ASTM International's Proficiency Test Program is a statistical quality assurance (SQA) tool enabling labs to compare, improve, and maintain performance in conducting tests per ASTM Intl. methods E8/E8M (Tension Test), E18 (Hardness Test), E646 (n value), and E517 (r value) on steel sheet materials.ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, . Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .ASTM E8 / E8M is one of the most common test method for determining the tensile properties of metallic materials, with the other being ASTM A370. First released in 1924, it was originally named ASTM E8-24T and is the oldest actively-used standard for the testing of metals. As with most standards, ASTM E8 has often undergone frequent, minor changes.

Lab-Potcher distributor

1.1 These test methods 2 cover procedures and definitions for the mechanical testing of steels, stainless steels, and related alloys. The various mechanical tests herein described are used to determine properties required in the product specifications. Variations in testing methods are to be avoided, and standard methods of testing are to be followed to .

1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable . following appendixes that relates to the Rockwell hardness test. List of ASTM Standards Giving Hardness Values Corresponding to Tensile Strength Appendix X1 Examples of Procedures for Determining Rockwell Hardness Uncertainty Appendix X2 1.5 Units At the time the Rockwell hardness test was developed, the force levels were speciÞed in units ofThe Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .Standard Test Method for Indentation Hardness of Organic Coatings: D2240: Standard Test Method for Rubber Property-Durometer Hardness: D2583: Standard Test Method for Indentation Hardness of Rigid Plastic by Means of a Barcol Impressor: E10: Standard Test Method for Brinell Hardness of Metallic Materials: E18: Standard Test Methods for Rockwell .

test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).

ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, .

ASTM E8 / E8M is one of the most common test method for determining the tensile properties of metallic materials, with the other being ASTM A370. First released in 1924, it was originally named ASTM E8-24T and is the oldest actively-used standard for the testing of metals. As with most standards, ASTM E8 has often undergone frequent, minor changes.Tensile properties of welded specimen were determined as per ASTM E8 Standard. The process parameters of the TIG welded butt joint of AA6082 plates were optimized using the Taguchi method.

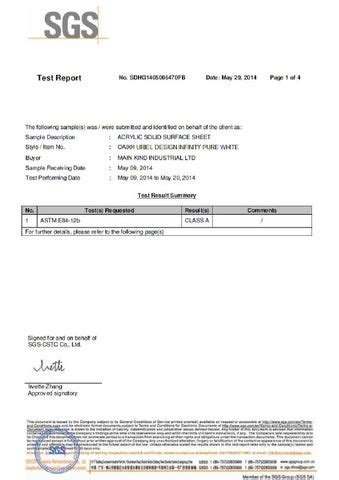

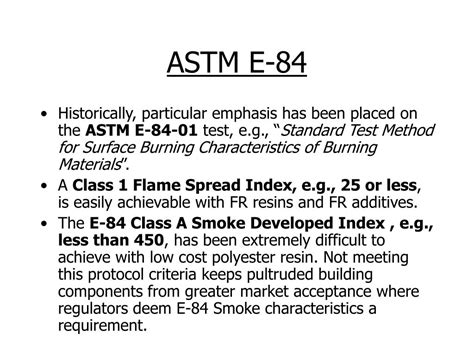

astm e84 test results

astm e84 rating meaning

ASTM E8 / E8M is one of the most common test method for determining the tensile properties of metallic materials, with the other being ASTM A370. First released in 1924, it was originally named ASTM E8-24T and is the oldest .ASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell . The Rockwell Hardness Test is considered to be more accurate and easier to perform than .

ASTM E10 Test Procedure. According to ASTM E10, the Brinell test is simple yet effective: indent the material with a hardened steel or carbide ball under a specified load. To that effect, the indenter size and the test load were determined using the Brinell Hardness Test ASTM E10 to standardize the hardness testing for labs and industries.

astm e84 pdf free download

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .%PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d . Significance and Use The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical char . Standard Test Methods for Rockwell Hardness of Metallic Materials E0018-08 ASTM|E0018 .

1.2 The gauge lengths for most round specimens are required to be 4D for E8 and 5D for E8M.The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area .

ASTM E18 Full Name. ASTM E18 – Standard Test Methods for Rockwell Hardness of Metallic Materials. Scope. ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to Brinell hardness.ASTM International's Proficiency Test Program is a statistical quality assurance (SQA) tool enabling labs to compare, improve, and maintain performance in conducting tests per ASTM Intl. methods E8 (Tension Test), E18 (Hardness Test), E646 (n value), and E517 (r value) on steel sheet materials.

2.1 ASTM Standards: 2 A356/A356M SpeciÞcation for Steel Castings, Carbon, Low Alloy, and Stainless Steel, Heavy-Walled for Steam Tur-bines A370 Test Methods and DeÞnitions for Mechanical Testing of Steel Products B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy ProductsTo determine the effects of quenching on the hardness of Type AISI 1045, 4140, and 4340 steels EQUIPMENT REQUIRED Blue-M Box Furnace (1) Jominey quencher. Rockwell Hardness Tester, C scale Belt Grinder Tongs / Gloves Metal Bucket MATERIALS REQUIRED Jominy specimens: AISI 1045, 4140, 4340 PROCEDURE Preheat Blue-M to 1600oF (per ASTM A255)All tensile test specimens are milled to precise standards in our dedicated machine shop to ensure that our data is reliable and accurate. Plate. ASTM A36 - Carbon Structural Steel; ASTM A516 - Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service; ASTM A572 - High-Strength Low-Alloy Columbium-Vanadium Structural .

Laboratory Valley pulp Beater distributor

Laboratory PFI Beater φ250×52 distributor

Resultado da Cannonball Bay is a 5-reel, 25-line online slot game with bonus spins, autoplay, wild symbol, scatter symbol, pirates, treasure and caribbean .

hardness test per astm-e8|astm e 84 fire rating